Why nutrient chemistry, ratios, and mixing order matter

Mixing nutrients isn’t just a routine task. It’s a chemical process. Modern fertilisers are carefully designed recipes, and the way they’re mixed determines whether nutrients are soluble and plant available.

Because nutrient mixing is such a precise chemical process, accurate measurement matters just as much as the nutrients themselves. Tools like the Bluelab Truncheon Nutrient Meter help growers confirm that what they’re mixing is actually what plants receive.

This is why the golden rule of mixing nutrients exists:

Always add nutrients to water and always follow the intended mixing order.

Understanding the chemistry behind this rule helps growers avoid nutrient lockout, inconsistencies, and hard-to-diagnose problems, whether growing at home or at commercial scale.

At Bluelab, we see many nutrient issues traced back not to the fertiliser itself, but to how it’s mixed and measured. That’s why consistent monitoring of EC and pH during mixing is a core part of nutrient best practice.

Nutrients are designed as recipes

Liquid nutrients are not single ingredients. They are engineered combinations of macro and micronutrients, each chosen and balanced to work together once diluted correctly.

Macronutrients such as nitrogen, potassium, calcium, and magnesium are required in large amounts. Micronutrients like iron, manganese, zinc, and copper are required in very small amounts, but they are just as critical to plant function. The challenge is that not all of these elements behave well together at high concentrations.

That’s why nutrient manufacturers don’t just think about what plants need. They think about how those nutrients chemically behave before plants ever see them.

Why A & B nutrients exist

A & B nutrient systems exist because certain nutrients are chemically incompatible when concentrated. A common example is calcium reacting with phosphates or sulfates. When these elements reach high concentrations, they can form insoluble compounds that precipitate from solution.

Once that happens, those nutrients are no longer available to plants. Find out more about common nutrient deficiencies and how to fix them.

To prevent this, incompatible nutrients are separated into two parts: A & B. Calcium is typically placed in Part A, while phosphates, sulfates, and many micronutrients are placed in Part B. They are designed to only come together safely after they have been diluted in enough water.

Why mixing order matters

When nutrients are added to a full volume of water, they dilute immediately. This reduces the chance of unwanted chemical reactions and allows each element to disperse evenly before the next is introduced.

When water is added to concentrated nutrients instead, small zones of extreme concentration can form. In these zones, incompatible nutrients may react before they have a chance to dilute properly. Even if the solution looks clear afterward, nutrient balance may already be compromised.

That’s why following the correct order is just as important as following the correct dose.

Mixing nutrients the way they’re designed to be mixed

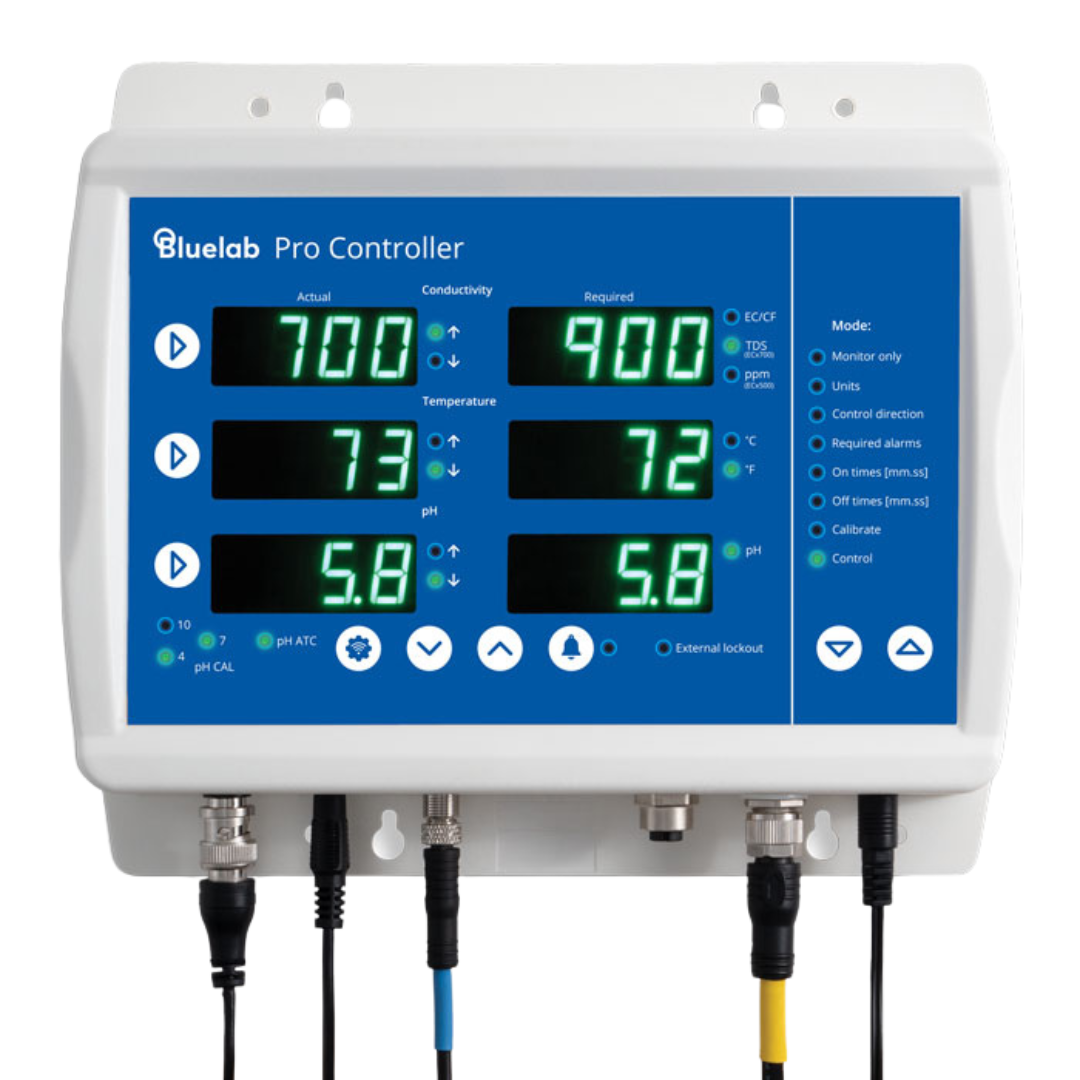

This process becomes far more reliable when growers can measure EC and pH in real time as nutrients are added, rather than checking only at the end. Reliable dosing systems such as the Bluelab Pro Controller Wi-Fi remove guesswork and help ensure nutrients are mixed exactly as intended.

A simple, chemistry-safe approach is:

- Start with clean water and know your base EC

- Add Part A and mix thoroughly

- Add Part B and mix thoroughly

- Add any additives only after base nutrients are fully diluted

- Measure EC, then adjust pH last

This sequence maintains nutrient solubility, preserves the intended ratios, and provides more reliable EC and pH readings. Always follow the manufacturer's guidelines and wear protective equipment.

Ratios matter as much as strength

Electrical Conductivity (EC) tells you how strong a solution is, not whether the nutrient balance is correct. It’s possible to hit the right EC while still delivering the wrong nutrient ratio if mixing is done incorrectly.

Plants don’t respond to EC alone. They respond to what is available in the root zone. Correct mixing helps ensure plants receive the nutrients they need in the proportions they’re meant to. Learn more about signs your plants are struggling with incorrect EC.

A practical tool for mixing and measuring

A practical tool for mixing and measuring

When mixing nutrients by hand, it helps to use a tool that supports accuracy and consistency. The Bluelab Truncheon Nutrient Meter is a popular choice because it can be used directly in the reservoir while mixing. It provides instant EC readings and, just as importantly, doubles as a sturdy mixing stick to help fully disperse nutrients as they’re added.

Good mixing isn’t just about numbers. It’s about making sure nutrients are evenly distributed throughout the solution.

Taking mixing a step further with automation

For growers looking to reduce manual handling and improve consistency, nutrient dosing can also be automated. Using the Bluelab Pro Controller Wi-Fi with PeriPods automatically doses nutrients in the correct order and quantities, helping maintain stable EC and pH levels over time.

This is especially useful in recirculating or commercial systems, where consistency across large volumes and multiple reservoirs is critical.

The golden rule of mixing nutrients is rooted in chemistry, not habit. Macro and micronutrients don’t all behave the same way, and A & B systems exist to keep incompatible elements apart until dilution makes them safe.

By adding nutrients to water in the correct order and mixing thoroughly, growers maintain nutrient availability, maintain proper ratios, and create more consistent conditions for plants to thrive.